Flexibility

Production setups with freely configurable system settings for fast change-overs before and during broadcast

Recurring use of event data with proactive conflict calculation

Flexible exchange of system components via drag & drop incl. transfer of processing parameters

Relocation of production areas by simple delegation

Control

Central, top-level controller system for all switching, adjustment and monitoring functions in the broadcast area

Graphically simplified presentation of complex system settings and states

Production-setups can be prepared offline, edited and selected on-the-fly in the system

NMOS IS-07 version 1.0 compatible transmission of time-critical information (e.g. for camera tally information, audio levels as well as button press and status information from control panels)

![[Translate to English:] Manufacturer-Independence](/fileadmin/_processed_/7/c/csm_Bubbles_Independence_9f941249b3.png)

![[Translate to English:] Manufacturer-Independence](/fileadmin/_processed_/7/c/csm_Bubbles_Independence_7195f53fa5.png)

Manufacturer Independence

Interfaces to all manufacturers who define broadcasting today and tomorrow

Return on investment even when switching to components from different manufacturers

KSC CORE includes a suitable interface for each device selection

- Integrated control of heterogeneous system structures

![[Translate to English:] PlugNPlay](/fileadmin/_processed_/8/b/csm_Bubbles_PlugNPlay_d7fef057ca.png)

![[Translate to English:] PlugNPlay](/fileadmin/_processed_/8/b/csm_Bubbles_PlugNPlay_84f7d5b3fc.png)

Plug & Play

Device scanner for automatic detection and configuration of system components through a wide range of supported protocols - including NMOS IS-07 for IP based environments.

Automatic detection of firmware and software versions of connected devices

Fully automatic standard configuration of newly connected control systems

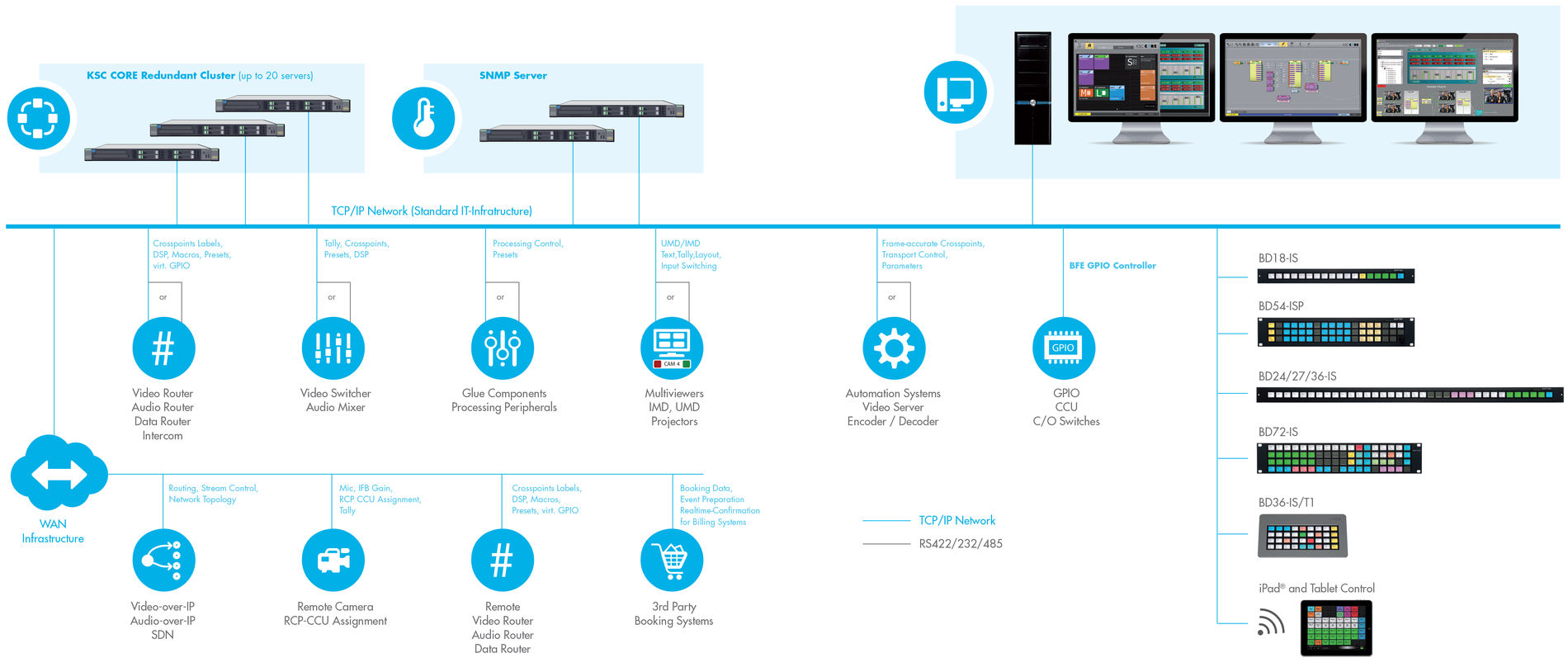

System Architecture

KSC CORE seamlessly integrates into existing network structures. A standard IT hardware backbone forms the basis of the solution. KSC CORE further enhances reliability with hardware and software redundancy concepts.

KSC Systems have taken care of intelligent broadcast control for more than 30 years. Talking native protocols to various manufacturers reduces the efforts on the manufacturer’s side and consequently enables the use of high-performance communication.

KSC CORE acts as the neutral intelligent communications translator between different devices no matter which physical control interface (TCP/IP or serial) is provided. Therefore, KSC Systems can seamlessly be integrated into existing (even vintage) broadcast device infrastructure.

By using an unlimited number of internal logic controls, KSC CORE adds to the standard functionality of device control and allows operators to design completely new functions.

At the intelligent and robust core of a KSC System, redundant servers in a cluster with up to 20 physical or virtual machines form the basis for 24/7 fail-safe operation. Automatic or manual (initiated from any KSC Control Panel in the system) fail-over switching guarantees for highest safety.

As monitoring and control systems are growing increasingly inseparable, KSC CORE introduces SNMP monitoring capabilities to the control system infrastructure by using a dedicated server unit for independent surveillance of all system components.

Hardware LCD control panels in a wide range of key formats, mounting options, and front panel designs made by BFE in Germany are available. Additionally, software based GUIs and Virtual Software Panels offer simplified and adaptable control.

BFE’s own hardware development and manufacturing delivers GPI/O interfaces and dynamic labeling UMDs as well as Sync-Interfaces for frame-accurate switcher- and automation systems operation.

When converting from serial control signals into the TCP/IP-world, KSC CORE relies on industry-standard components with a proven track record of hundreds of installations.

KSC CORE Server Software

Is the KSC CORE software installed on the server unit and marks the basis for every KSC CORE control system. Depending on the area of application, the server software’s basic functionality can be further enhanced with KSC CORE Server Software Extensions, making your application your own.

KSC CORE Client Software

Is the KSC CORE software running on a client workstation to setup and control KSC CORE. The client can also be tailored to your specific needs by various KSC CORE Client Software Extensions, such as the GFX Unit for easily designing functional GUIs, or Matrix View for matrix-based routing and real-time status information.